Two Continents -- One Team

Rikon Power Tools

What happens when a young woman from Vermont and a Chinese industrialist join forces? You get a power tool company. Erin Riley went to China several years ago to provide some marketing expertise to Robert Chen of QCR … a manufacturer who had been making power tools for some time. After a short while, Erin decided that she could run a power tool business as well as anybody – so she and Robert kicked off Rikon. Erin went back to Boston for a couple of weeks and then flew back to China and stayed for over four months. That was the beginning. I first met Erin in a small booth at the Chicago Hardware Show, and if I remember correctly, she had three tools in the booth. As Robert told me, those first years were very tough. Later, Steve Mangano was brought into the picture to provide insight into the woodworker’s point of view and some input into cool new tool features and the picture became clearer.

So in a few years, Rikon has become a tool company to be reckoned with. Their band saws have gained excellent reputations and they are moving forward with their own designs on many stationary tools. It seems to be working for them.

I was really impressed with the teamwork I saw between the US crew and the Chinese team. The true partnership with the Boston group and the people in Qingdao is unique in many ways from my observation. It removes the inevitable tension between two companies and their necessary primary concern of ensuring their own profitability over all else. In this case they are all in the same boat whether it is taking on water or steaming full speed ahead.

As I stated in an earlier entry, business is not conducted between companies, it is done between people. And I saw some great chemistry between the different folks at Rikon. No one knows better than Robert Chen that the power tool business is very competitive, but good teamwork always provides an advantage. Add to that a philosophy of constant product improvement and things start to look bright.

I’ve been told a couple of things to look for from Rikon, but I will let that cat out of the bag when the time is right. But if I were you, I’d keep my eyes peeled for new tools from the Qingdao/Boston team.

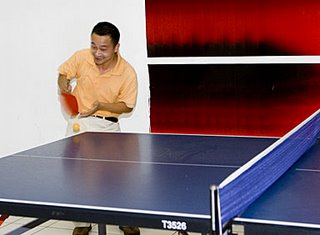

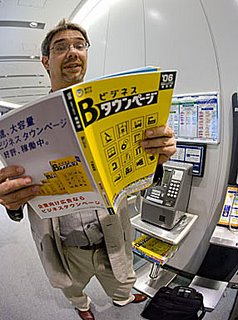

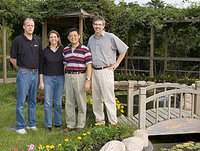

Photos top to bottom:

A long time QCR employee. Steve Mangano, Erin Riley, Robert Chen and your intrepid editor. Rikon band saw. 3D design work being done in the Qingdao facility. The Rikon crew ... plus a hanger-on.