Vertically Integrated

Laneton Machinery Limited

My last factory visit was not what I had expected. I contacted Patrick Chen of Laneton Machinery, at the behest of Steel City Tools and our visit was set up. Laneton turned out to be the most vertically integrated factory of my entire visit. Vertically integrated is just a cool term that manufacturing folks use to say, “We make everything”. So instead of buying say, the plastic housings of a tool, they buy an injection molder and make the parts instead. This does a couple of things; it gives you more control over how precisely a product is made, and it keeps your “secrets” in house. In other words, your competitor won’t walk through your subcontractor’s plant and figure out what you are doing. As you might also deduce, investing in the equipment can be a big expense … so it adds a bit to the manufacturing gamble.

Laneton makes many products for Steel City Tools, and they basically construct them soup to nuts. Everything from making the motors (Laneton makes both universal and induction motors), to machining the cast iron, to stamping, bending and welding the sheet metal. In doing so, it is Laneton’s contention that by doing so, they have more control over both quality and schedule.

I have to say I was very favorably impressed with their facilities. The natural light was very impressive and the size of their buildings was remarkable. The buildings were clean and seemed very efficient. And the variety of tasks that they can do is something that I had not previously observed.

Qingdao Sightseeing

That afternoon I got to spend some time just seeing the sites in the city of Qingdao. It is a beautiful city on the coast. In fact, it will be the location of the 2008 Olympic sailing competitions. The old part of the city reflected influence of its German occupiers from the early part of the 20th century. Its new additions are modern and very well done. One reason I found it so attractive is that it is such a “small” city – only a million people. All in all it was a wonderful afternoon that I will remember for a long time.

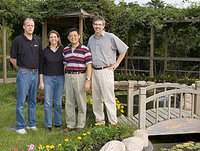

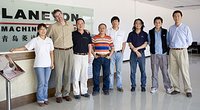

Photos top to bottom:

Steel City jointers being assembled. Patrick Chen and your attentive editor. In the sheet metal shop. The whole gang at Laneton Machinery. The highest point in Qindao and the view from that building. Grace and your apparently tall editor on a Qingdao beach.